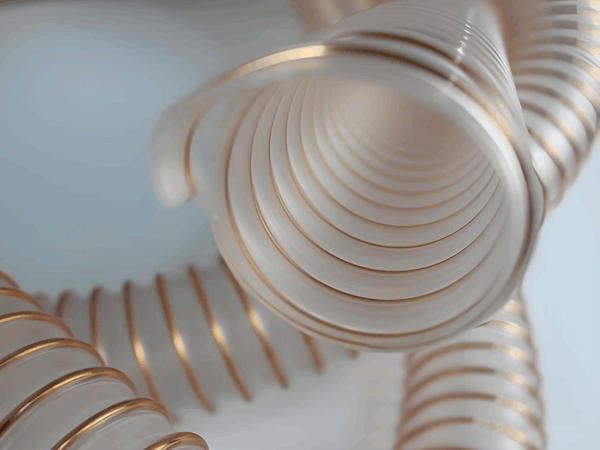

Polyurethane (PU) hoses are renowned for their exceptional versatility and durability, making them a popular choice across various industries. Let’s dive into what makes PU hoses stand out and their wide range of applications.

Key Features of PU Hoses

- Exceptional Flexibility: PU hoses maintain their flexibility even in extreme temperatures, ensuring reliable performance in both hot and cold environments.

- Durability: The robust nature of polyurethane provides excellent resistance to wear and tear, making these hoses ideal for demanding applications.

- Chemical Resistance: PU hoses can withstand exposure to a variety of chemicals and solvents, making them suitable for industrial use.

- Lightweight: Compared to traditional rubber hoses, PU hoses are significantly lighter, which simplifies handling and installation.

Applications of PU Hoses

- Industrial Use: PU hoses are commonly used in manufacturing for transporting air, water, and other fluids.

- Automotive Industry: These hoses are used in fuel systems and pneumatic applications within vehicles.

- Food and Beverage: Certain food-grade PU hoses are used for transferring liquids and gases in food processing.

- Medical Field: PU hoses are utilized in medical devices and equipment due to their flexibility and durability.

- Construction: Used for conveying air and water on construction sites, PU hoses are valued for their resilience and ease of use.

Maintenance Tips for PU Hoses

To ensure the longevity and optimal performance of PU hoses, consider the following maintenance tips:

- Regular Inspections: Check for signs of wear, cracks, or damage regularly and replace any compromised sections promptly.

- Proper Cleaning: Keep the hoses clean to prevent chemical buildup that could degrade the material.

- Correct Storage: Store PU hoses in a cool, dry place away from direct sunlight and extreme temperatures to prevent premature aging.

Why Choose PU Hoses?

When compared to PVC hoses, PU hoses offer superior flexibility, durability, and chemical resistance. Although they may come at a higher initial cost, their long-term performance and reliability make them a cost-effective choice for many applications.